Background:

- Postdoc: Biomedical Engineering, Massachusetts Institute of Technology, USA.

- PhD: Mechanical Engineering, Massachusetts Institute of Technology, USA.

- MASc: Electrical Engineering, University of British Columbia, Canada.

- Undergraduate: Electrical Engineering (Nanotechnology and Microsystems), University of British Columbia, Canada.

Research:

Drug Delivery: We have few publications on this project that are in preparation/submission. You can refer to my CV for more information about our progress.

Artificial Muscles: Also known as muscle-like actuators are devices/materials that can expand/shrink in length, bend, or rotate in response to an external stimulus such as heat, electric field, magnetic field, light, fluid pressure, redox reactions, etc. I have worked on the following types of artificial muscles at a system level and also device level.

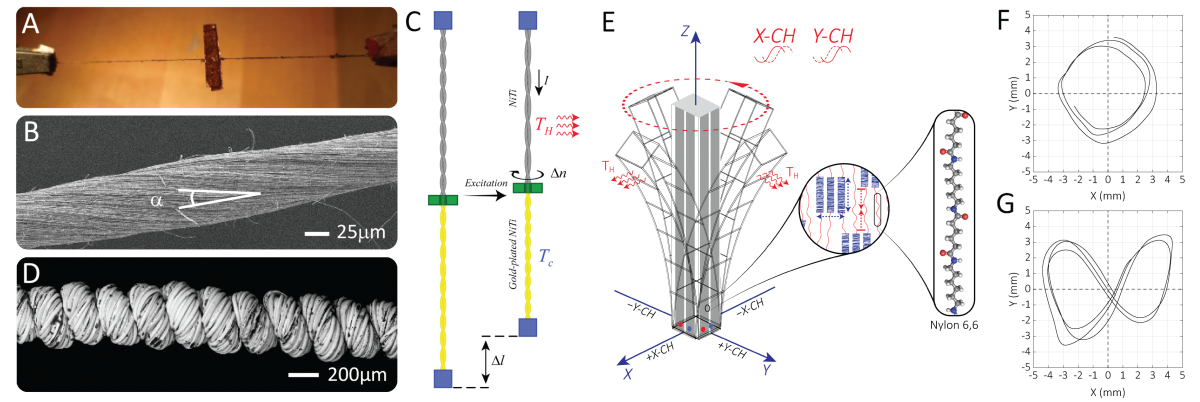

Thermal actuators: As the name suggests, thermal actuators actuate upon heating. The heat can be generated via different mechanisms such as passing a current through a conductive coating (i.e., Joule heating), light/matter interaction (i.e., high power laser), convective flow, etc. For the first time, I introduced niobium nanowire yarns as a promising alternative to carbon nanotube yarns. My colleagues and I showed that by infiltrating twisted niobium nanowire yarns with paraffin wax, we could make a torsional/linear actuator. Upon Joule heating, the paraffin wax melts and expands in volume by almost 30% which generates the driving force for the actuation (Figure 1A, B). Later, I showed the torsional actuation is not unique to paraffin-infiltrated nanowire yarns and we can generate torsional actuation from a shape memory alloy fine fiber twisted-yarn as well (Figure 2C). In a different project, my colleagues and I showed that by twist-coiling nylon 6,6 filaments and fibers we could make a very low-cost linear actuator that beats human's muscles in terms of strain, output power, and energy density (figure 2D). Aside from linear and torsional actuators, I made a bending actuator from nylon 6,6 which can be controlled to bend in different directions (Figure 1 E-G).

Figure 1 – (A) Twisted niobium nanowire yarn actuator. (B) Niobium twist spun with a twist angle of 13°. (C) Diagram illustrating the working mechanism of an SMA torsional actuator. The bottom yellow part of the yarn represents the gold-coated section of the yarn. (D) SEM image of a twisted silver-plated nylon linear artificial muscle. (E) Schematic of the nylon multi-directional actuator. By heating one side of the actuator, the amorphous chains (red lines) shrink in length and the crystalline regions (blue lines) expand in volume. The result is the surface contraction of the beam at its heated surface which creates the bending motion. (F-G) The coordinate of the tip of the actuator by applying the periodic inputs.

Pneumatic actuators: These actuators work based on fluid pressure inside a compliant/expandable bladder. I have demonstrated torsional pneumatic actuators which can reversibly rotate by three full rotations and generate peak torsional speed of 1,800 RPM with a specific torque of 3.6 N·m/kg (similar to that of ungeared electric motors).

Electrochemical actuators: As side projects, I have made bending actuators with PEDOT and torsional actuators with niobium nanowire yarn. For PEDOT actuators, the electrochemical redox reaction is responsible for the actuation while for the niobium nanowire yarns, charge injection in the double layer.

More on the actuation mechanisms, applications, and limitations of the mentioned actuators can be found in our recent invited review paper.

Publications on this topic:

- Niobium Nanowire Yarns and their Application as Artificial Muscles (Advanced Functional Materials)

- Artificial Muscles from Fishing Line and Sewing Thread (Science)

- Simple and strong: twisted silver painted nylon artificial muscle actuated by Joule heating (SPIE)

- Multidirectional Artificial Muscles from Nylon (Advanced Materials)

- Bending artificial muscle from nylon filaments (SPIE)

- Fast Torsional Artificial Muscles from NiTi Twisted Yarns (ACS Applied Materials & Interfaces)

- A torsional artificial muscle from twisted nitinol microwire (SPIE)

- Artificial Muscles: Mechanisms, Applications, and Challenges (Advanced Materials)

Some of our artificial muscle works were on news outlets including:

- MIT News.

- Advanced Science News.

- CBC (Canadian Broadcasting Corporation).

- Vancouver Sun (local newspaper in Vancouver).

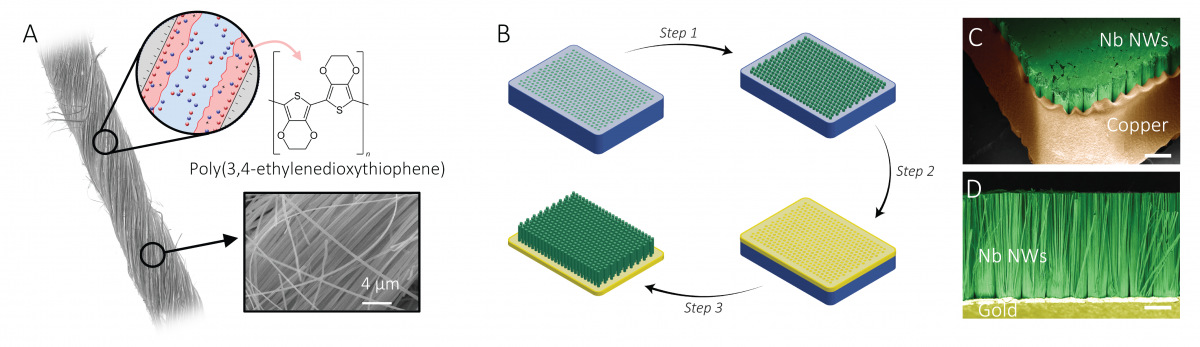

Energy Storage: Capacitors exhibit remarkable power density while batteries have excellent energy density. Supercapacitors offer a good combination of energy and power density. I demonstrated two different supercapacitor designs from niobium nanowires. The first design is in the form of a yarn, suitable for wearable, flexible, and stretchable devices (Figure 2A) and the second design is a planar supercapacitor suitable for micro-electronics (Figure 2B).

Figure 2 – (A) Addition of PEDOT to the interior of the nanowire structure increases capacitance. Inset top: Electrolyte and PEDOT within the yarn are shown in blue and red colors respectively. Red and blue spheres represent positive and negative ions. Inset bottom: scanning electron microscopy image of the niobium nanowires. (B) Fabrication steps of the VA-NbNW electrodes. (C,D) False color SEM images of step 1 and 3 outcomes.

Publications on this topic:

- High-Performance Supercapacitors from Niobium Nanowire Yarns (ACS Applied Materials & Interfaces)

- Vertically Aligned Niobium Nanowire Arrays for Fast‐Charging Micro‐Supercapacitors (Advanced Materials)

We had news converage for this project and the work was featured on some news outlets including:

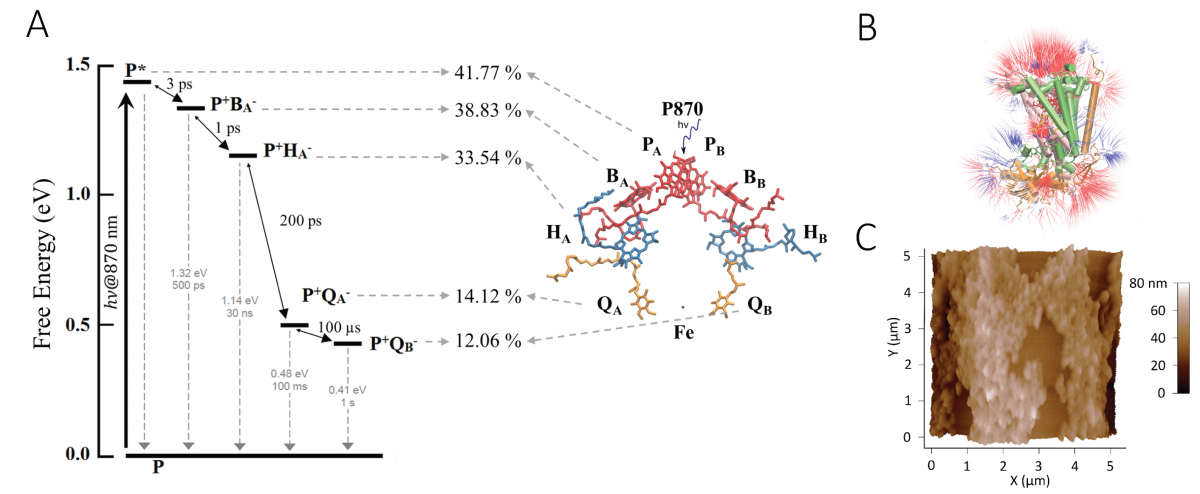

Bio-photovoltaic: We receive peak power of 1-1.3 kW/m2 from the sun on a sunny day. It is very desirable to harvest this light, store it, and use it during low light conditions. There are many different designs for solar cells. In this project, we tried to adopt nature's solution for harvesting light for solar cell application. The project focus was on the design and fabrication of different architectures for utilizing reaction center of Rhodobacter sphaeroides in a solar cell device (Figure 3A, B). I proposed using electrospraying of RCs on HOPG for fabrication of photo-active electrodes (Figure 3C). In collaboration with two postdocs and three PhD students at UBC, we could show that the RCs not only survive the electrospray process but also yield peak photocurrent densities that were the highest value reported to the date of publication.

Figure 3 – A) Left: A schematic of the energy levels, recombination time constants, and theoretical ultimate power conversion efficiencies for each cofactor in the R. sphaeroides RC. Right: Crystal structure showing the position of RC cofactors (carotenoid not shown). B) Red and blue field lines represent the negative and positive charges respectively on the surface of the RC. The H subunit is in orange, L in pink, and M in green. BChls are in red, BPhes in yellow, and Qs in blue. C) Topography image of an HOPG surface after RC electrospray and rinsing. One lightly deposited area is displayed to show the contrast between the coated and clean HOPG.

Publications on this topic:

- Photoactive Electrodes Incorporating Electrosprayed Bacterial Reaction Centers (Advanced Functional Materials)

- Photocurrent generation by direct electron transfer using photosynthetic reaction centres (Smart Materials and Structures)

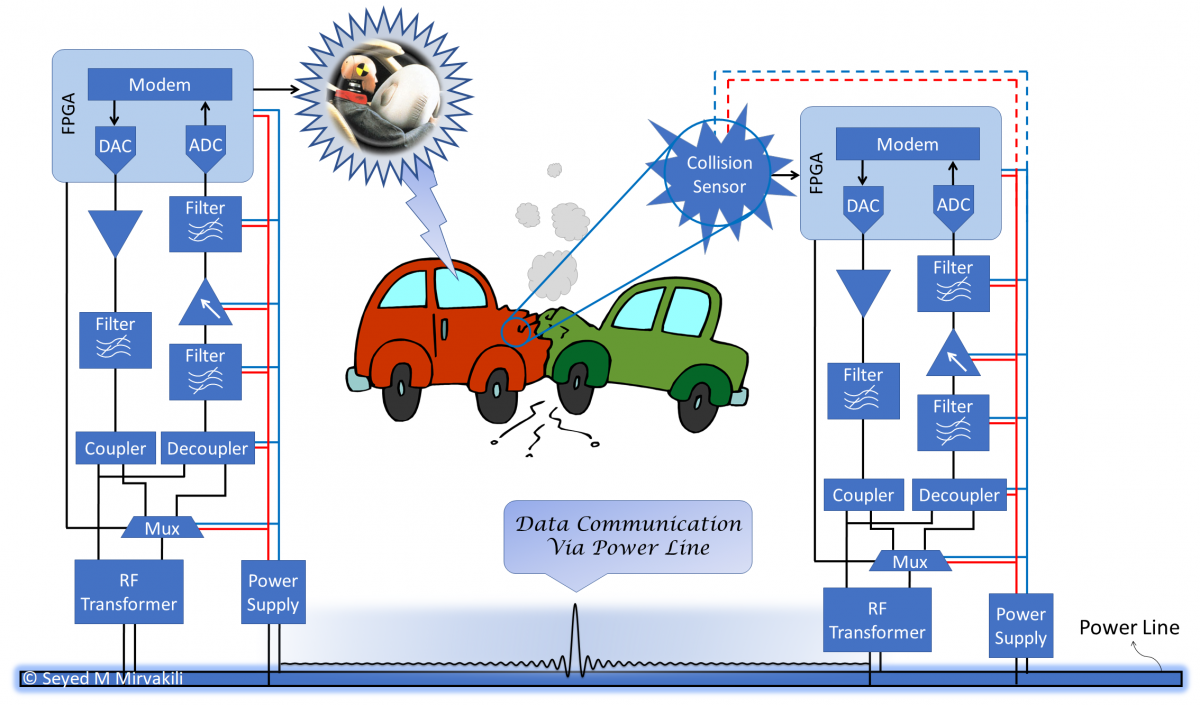

Power Line Communication: In-vehicle power line communication (PLC) holds great promises as an enabler of in-vehicle communication without increasing weight, volume, or cost of the wiring harnesses (Figure 4). I designed, built, and tested a power line communication interface circuit for vehicular digital communication and collaborated with another team member on measurement of channel characteristics (i.e. transfer function) of a Pontiac Solstice using Vector Network Analyzer (VNA).

Figure 4 – Big picture schematic of an in-vehicle power line communication system.

Publications on this topic:

Teaching:

- Received Kaufman Teaching Certificate at MIT (2015).

- Direct adviser for 22 students for their undergarduate thesis (2011-2017).

- Co-adviser for one master students and direct adviser for one PhD student (2012-2014, 2018).

- Served as a teaching assistant for about 300 students for:

- Advanced Instrumentation and Measurement (2.131) graduate course at MIT (3 semesters).

- Instrumentation and Measurement (2.671) undergraduate course at MIT (1 semester).

- Instrumentation Design Laboratory (EECE 474/375) undergraduate course at UBC (3 semesters).

- Nanotechnology in Electronics (EECE 401) undergraduate course at UBC (1 semester).

- Tutoring (1 semester).

- Designed and taught a lab course on the basics of electronics to peers and classmates at highschool (1 academic year).

Leadership:

- Leader of self-initiated group projects at UBC (2011-2013).

- Founder of Seron Electronics, BC, Canada (2011).

- Project Leader at UBC (2007-2008).

- Colorimeter.

- Optical Heart Beat Monitoring.

- Sonic Tomographic Imaging Device.

- Energy Efficient Rapid Transit System Prototype.

Awards and honors:

- 2nd place in de Florez competition (Innovation Award, MIT, 2017)

- Sontheimer Travel Award in Mechanical Engineering (MIT, 2017)

- Neekeyfar Fund Award (MIT, 2016)

- 3rd place in de Florez competition (Innovation Award, MIT, 2015)

- NSERC – Michael Smith Foreign Study Supplements (Research Award, MIT, 2014)

- Alexander Graham Bell Canada Graduate Scholarship (CGS D3) (Research Fellowship, MIT, 2014)

- Finalist for Killam Graduate Teaching Assistant Award (Teaching Award, UBC, 2013)

- Finalist for Vanier Canada Graduate Scholarship (Research Fellowship, UBC, 2013)

- Four Year Fellowship (FYF) For PhD Students (Research Fellowship, UBC, 2013)

- Faculty of Applied Science Graduate Award (Research Award, UBC, 2012)

- Faculty of Applied Science Graduate Award (Research Award, UBC, 2011)

- Faculty of Applied Science Graduate Award (Research Award, UBC, 2010)

- NSERC Top-up Award from ICICS (Research Award, UBC, 2010)

- Alexander Graham Bell Canada Graduate Scholarship (CGS M) (Research Fellowship, UBC, 2010)

- NSERC-USRA (Research Fellowship, UBC, 2010)

- NSERC-USRA (Research Fellowship, UBC, 2009)

- Dean's Honor List (Distinction, UBC, 2008)

- Eric P. Newell Leadership Award in Engineering (Leadership Award, UBC, 2008)

- Trek Excellence Scholarship (Academic Award, UBC, 2008)

- NSERC-USRA (Research Fellowship, UBC, 2008)

- Summer Scholarship (Academic Award, UBC, 2008)

- Dean's Honor List (Distinction, UBC, 2007)

- President's Entrance Scholarship (Academic Award, UBC, 2007)

- Khwarizmi Innovation award (Innovation Award, 2003)